Virginia, Pat, Beth, Sue H and I arrived eager to learn how to make a floor rug or in Pat’s case, a table-runner under the expert tutelage of Liz Odd.

Tables were set and instructions were handed out by Liz. We had all arrived with an idea of what we wanted to do. In my case, a simple striped floor mat similar in design to one of Nancy’s creations. I wanted to learn the technique and not be side-tracked by more complex design or technique. Liz soon put paid to that! She showed us various samples of her work and designs from invitations to indigenous art exhibitions and urged us to think about design, colour and use of our pieces. We could felt both sides with different designs if we wanted too. As with all felting, Liz made us realize that we could let our imaginations run wild! This led me to change my design whilst keeping the technique simple and to play with shape and colour. Beth and Virginia decided to felt with different designs the backs of their pieces too.

Beth had returned to felting after a break of three years and she was flying along, using up materials from her shed. A lovely soft mauve hued bat with lots of brightly coloured pre-felted pieces, scatterings of wool and other embellishments on top and a totally different pattern and colour scheme on the bottom.

Virginia wanted to make a rug for her living area and she had her design and colours all planned. She started with a ‘Nancy’ bat, then a layer of cotton lawn, topped with a fine layer of wool laid in one direction, topped with a double layer lightweight Felbi bat. She then laid a scroll like design on top with wool yarn.

Pat was carefully cutting out her design to use on her table runner and Sue was being very social while she worked out what she wanted to do which turned out to be a stunning rug.

Pat’s table runner was laid on a ‘Nancy’ bat, topped with fabric and then wool and her pre-felt design.

Sue laid out her design on top of a ‘Nancy’ bat. Her rug covered two tables which when dry was easy to manoeuvre but once wet it took two people to lift and carry out to her car!

As the day wore on the creativity ebbed and flowed and Liz monitored progress, providing useful tips and tricks and hands on assistance such as trimming edges, design advice, placing pieces and wetting down.

Once we had laid out the design, it was time to dry roll our pieces and then check that the design was still in place and that there were no holes where the bat could come through. Once finished with that process it was time to wet down and finish the felting process, remembering to keep checking, getting rid of excess water and stretching.

The day went all too quickly and we all headed off with our efforts to finish at home.

Everyone had a great time. Lessons learned – positive and negative:

- If using fabric between your wool layers, wash it first to avoid issues with different shrinkage rates between wool and fabric, the effect of any water resistant chemical applied to the fabric and dye running. Liz suggests washing all fabric before use and making a note if it runs or has other problems.

- In Virginia’s piece she commented that another layer of wool in a different direction between the bats would have resulted in more even felt and a thicker layer of wool on top would have been preferable.

- Some of the bats were water resistant in patches and difficult to wet so we ended up with too much water and soap. The only solution is to mop up extra water and soap as it is very difficult to tell which parts of the bat will be resistant.

- If you have a plastic table similar to the ones we use, use the table edge to get straight edges and rounded corners when cutting and trimming.

- keep stretching the piece between rolling to get straight edges

- and for new felters like me, use a tumble dryer to felt big pieces. Don’t over- do it. If using a tumble dryer, less is better ie keep checking every five minutes for shrinkage and stretch edges to keep it straight.

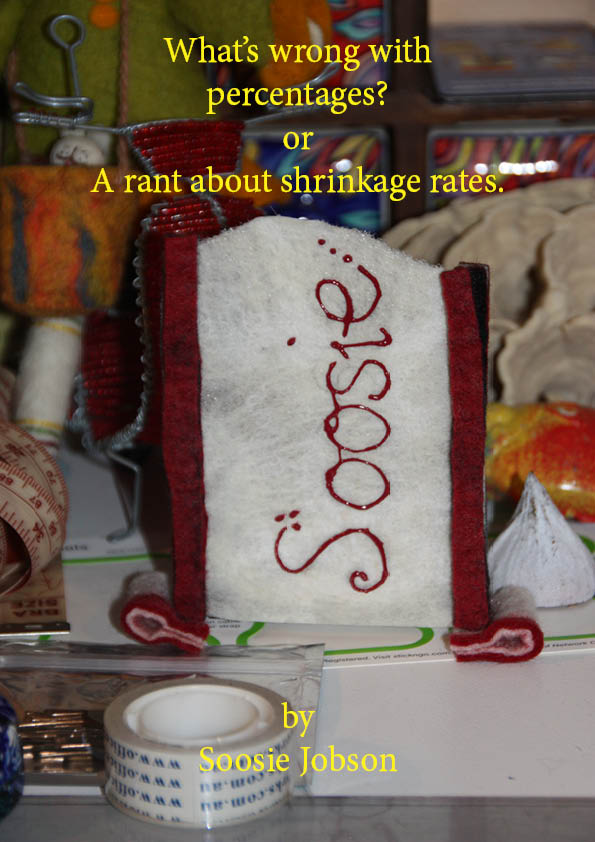

POST SCRIPT: At the October Show and Tell, we brought along our pieces for Liz to critique. Pat had used some stitching on her table runner which brought out the colour and texture of her table-runner. Sue was not present so we weren’t able to see her stunning rug. Beth decided that she was going to stitch hers too to bring out the colours and add texture. Virginia’s was finished and looked lovely and mine needs some more felting to harden the edges.

A huge thank you to Liz who not only provided great tutoring in class but followed up with each of us after class to offer advice and help.